Ahlstrom Kamyr Kneader Disperger

Ahlstrom Kamyr Kneader Disperger

Description

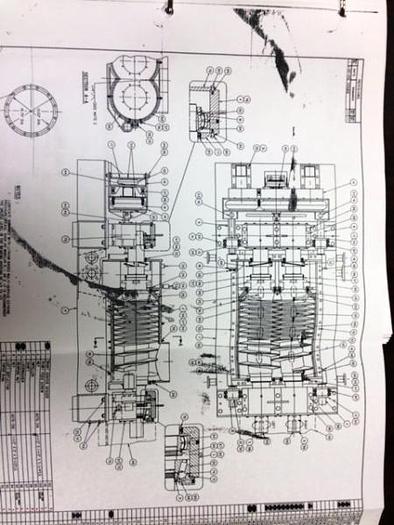

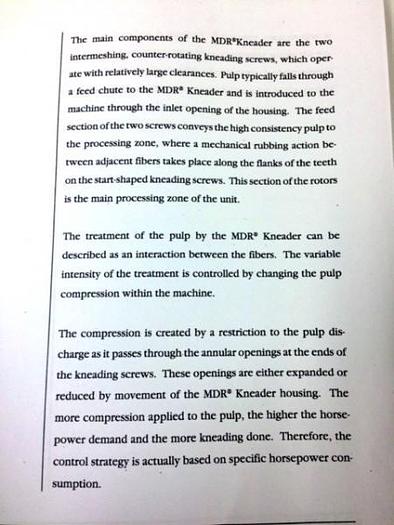

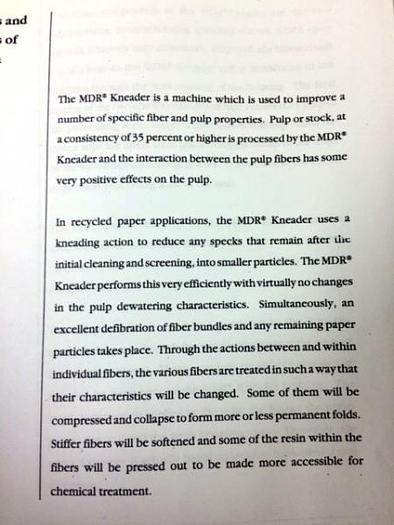

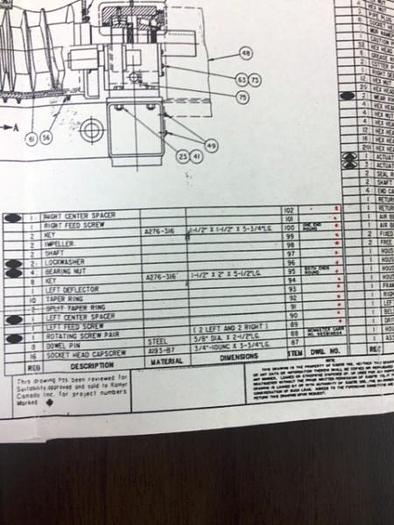

AndritzAhlstromMDR2000HotDispergerKneader AHLSTROMMDRH200034"DISPERGER Themechanicalagitatingdeviceusedinthepracticeofstep(c)is,forexample,adispersingdevice,suchasanMDR®disperserassoldbyAhlstromMachinery,oradeflakingdevice,suchasadeflaker-typepump,oranysimilardevicewhichagitatestheslurrytodisruptfiberflocsandreducecontaminantsizeandimprovecontaminantdistribution. Also,toprovideatreatedfibrousmaterialforsubsequentprocessing,itmaybebeneficialforthefiberseparator12toincludeotherequipmentsuchasafiber classifier,adispersionsystem,andakneadingsystem.Examplesofdispersionsystemsinclude:Krima(availablefromCellwood,CornerandFMW),Diskperser(availablefromGL&V),MicarProcessor,Diva(basedonConflo+HiPreheaterfluffer/steammixer.availablefromMetsoPaper/Fiber);Frotapulper(availablefromMoDoMekan),Triturator/KneadingDisperser(availablefromThermoBlackClawson,Lamort);Disperger(availablefromVoithPaper).Examplesofkneadingsystemsinclude:MDRKneader(availablefromAndritz-Ahlstrom),UltraTwin-Flyte(availablefromThermoBlackClawson),Kneading-Disperger(availablefromVoithPaper). 885kneadingzoneislongcomparedtodiskdispersionandcanbeeffectiveinimpartingcurlorentanglement.OneexampleofakneaderistheVoithSulzerKD-500kneadingdisperger(sotermedintheabove-referencedarticleofHostetter-kneadingcanbeconsideredasoneformofdispergingforthepurposesofthepresentinvention).TheAhlstromMDR®Kneadercanalsobeused.Anotherexampleofakneaderisprovidedin 2.2.Low SpeedKneading Lowspeedkneadingimpartsaratherprolongedmechanicaltreatment(someminutes)toalargemass offibrousmaterialwithamoderateshearingeffect.Thisactionisrelatedtotherelativelywideinterbar clearanceandslowrotation.Rotationalspeedsarenormally100–200rpm,withafewexceptionsat higherspeed.Thedispersioneffectresultsmainlyfromfibre-to-fibrefriction(rubbingaction).In general,low-speedkneadersaredevicesinwhichthepulpisfedinbyascrewandheldbya dischargedoorasitistransferredunderpressurebetweenrowsoffingersonashaftandotherson thestatorwall. Kneadingtechnologyforlowspeeddispersionconsistsofequipmentwithasingle–shaft( Erwepa, Voith-Sulzer , Lamort-Fiberprep , Maule ),ortwoshafts( Shinhama,Modomekan-Ahlstrom-Kamyr ), speciallydevelopedforhotdispersionorresultingfromtechnologytransferfromstockmixers( Micar Black-Clawson ).AtypicalsingleshaftkneaderisillustratedinFig.6. Variousdesignsareusedfordoubleshaftkneaders The Shinhama low-speedkneader,illustratedinFig.7,hastwocounter-rotatingshafts,oneturningat 95rpm,andtheotherrotatingslightlyfasterat110rpm[30].Thedevicepreviouslycalled "Frotapulper"( Modemekan-Kamyr ),andcurrentlyreferredtoas"MDRKneader,"( Alhlstrom-Kamyr ) lookslikealow-speedkneader,butthetwoscrewscounter-rotatesynchronouslyataspeedof900- 1800rpm(intherangeoftheofhigh-speeddispersers).Thedevicecalled"Micar"( Black-Clawson ) runsatintermediatespeed(400-500rpm)[12]. Thedischargedoorcontrolsthevolumeofpulpinthedevice.Stockmovesthroughthedeviceata ratherlowspeed.Differencesinstockvelocityarecreatedinsidethemachine.Thestocknearthe rotorismovingatahighervelocitythanthestocknearthestatorwall.Inthedoubleshaftkneader,the rotorsturninoppositedirectionscausingashearingeffectwhenthestockchangesitsdirectionof movement).Thesedifferencesinvelocityinducethefiber-to-fiberfrictionandthedispersioneffect. Agentlekneaderincludingdewateringequipmenthasbeenproposed[31]andisillustratedinFig.8.It consitsof3cylinders.Atthefirsthalfofeachcylinder,ascrewbootsthestockforwardandatthe latterhalf,thestockproceedsthroughkneadingblades.Whenthestockproceedsfromonecylinderto another,therotationofshaftaltersviceversa.Inthethirdcylinderchemicalscanbeintroduced.The3 cylindersallowincreasingthekneadingtime.Eachcylinderisequippedwithasinglemotorpermitting anindependentcontrolofeachofthemsothatitispossibletoadjusttheunittoavariationofstock and/ortargetqualityofthepulptobeproduced.Inthiskindofdevice,nosteamintroductionis requiredasthetemperaturecanreachspontaneous50to90°Cduetothefrictioninvolvedinthe kneadingparts.Theenergyconsumptionisbetween40and80kWh/T.Themaindifferencewiththe otherlow-speedkneaderisthepresenceofdewateringzoneinthefirstandsecondcylinder.Thi operateattemperaturesupto150°C.Theseconditi onswererequiredinboardmillsforasphalt dispersion. Forbothtypes,theenergyconsumptionisintherangeof35–100kWh/t,withtypicalindustrialvalues intherange60-80kWh/t.Varioustechniquescanbeusedtoadjusttheenergyconsumption dependingonthedeviceused.Theseapproachesincludeadjustingthepressureonthedischarge door,gapbetweenrotorandstator,inletconsistency,etc. Inthedeinkingplant,dispersioncanbecombinedwithbleaching.Bleachingchemicalscanbe introducedattheheatingscreworattheinletofthedispersionunit,whichcanbeusedasmixeror bleachingreactor.Dependingontheoperatingtemperatureandthedeviceused,retentiontimemay ornotberequiredafterthedispersionunit. Generallythepulpdischargedfromalow-speedkneaderdoesnotrequiredilutionandbleachingis conductedatthekneadingconsistency.Thepulpcanbedischargedatoperatingconsistencyinsome high-speeddispersersbutgenerallyadilutionisrequiredfordischarge.Inthiscasestoragefor bleachingextensionisnotpossible. 4.DISPERSION Varioustypesofcontaminantscanbedispersedbyusinghigh-speeddispersersorlow-speed kneaders.Theseincludebitumen,waxes,stickies,specks,residualink,andhotmeltcontaminants suchasbookbindingorcontainersealingglues.Dispersionofwet–strengthpaperisalsoreported [71]. Itmustbebroughttotheforethatdispersingtreatmentinducesfragmentationoftheparticlessothat theycannotbeseen.However,evenifthepulpseemstobecleaner,thesecontaminantsarestill presentinthepulpbuttheyarenotvisible.Iftheyarenotremovedduringthenextstepoftheprocess, someproblemscouldappearinsomecasesduringpapermakingandduringthefinaluseofthe product Atta High-qualityprintoncoatedpaperswithinkshardenedbydryingcanalsocausespecks,whichresult frombindingbetweenthepigmentandthecoatingmaterial.Recoveredpapers,whichproducethese kindsofspecks,arealsoglossymagazines.PapersprintedbyunconventionalprocessessuchasUV- curedinks[49]orsomegradesofmoderndigitalprintalsoinducespeckformation. AlargerecyclingstudyofpapersfocusingonspeckleddeinkedpulpandUV-varnishedpapers particularly,hasbeenperformedintheCentreTechniqueduPapier[50]. First,thespecksfromvariousoriginshavebeen comparedregardingtheirdifficultytobe dispersedbykneading.Trialswereperformed 99.9 Kneadingefficiency(%) Resistantcoating attheCTPdeinkingpilotplantwithalowspeed kneader,whichisahotdispersionunit(TL0 from Lamort ,20kg/hr).Resultsfromresistant coatedpapersandUVvarnishedprintedpapers arereportedinFig.12[50]. 99 90 UVvarnish Lowenergyissufficientfordispersionofspecks fromresistantcoatedpapers.Withtreatmentat currentindustrialenergyconsumption(60 kWh/t)thepulplookscleantothenakedeye. Higherenergyconsumptionisnecessaryfor dispersalofspecksfromUVvarnishedprinted papers.Gooddispersioncanbeobtainedat hightemperatureandwithhighenergy consumptioninaslowspeedkneader. Energyconsumption(kWh/t) 40 60 80 100 120 140 160 180 Pulpfromunprintedwastepapercontaminatedwith4 %ofapulpproducedbypulpingUVvarnishedprinted papersor10%ofapulpproducedfromwaterresistant coatedpapers(offsetprinting).Influenceofenergy consumption.Pilotplanttrials(pulpconsistency32%, temperature90°C).Efficiencyiscalculatedasspec k areareduction(speckslargerthan100µm). Fig.12 Hotdispersionofspecksinalowspeed kneader[50] . TheworkhasbeenfocusedonUV-varnishedpapers;kneadinganddispersinghavebeeninvestigated aspartofthisstudy.Trialshavebeenperformedinpilotplantsofmachinerysuppliersinorderto optimizethedispersionofvisiblespecks.PulpfortrialswasproducedatCTPbyblendingapulpfrom unprintedpaperswith2%contaminatedpulp.ContaminatedpulpcontainedUV-varnishedprinted paperspulpedfor20minat14%consistencyand50°Cwithdeinkingchemicals.Fig.13toFig.15 showresultsfromtreatmentofcleanpulpmixedwith2%UV-varnishcontaminatedpulp( Unprinted wastepaperincluding2%ofUVvarnishedprintedpapers.Particleslargerthan100µmwereconsidered. Efficiencyiscalculatedasspeckareareduction) . Bothlow-speedkneadersandhigh-speeddispersersareefficientinreducingthesizeoflargespecks asshownFig.13[51]. Influenceofenergy consumption, pulp 99.9 Dispersionefficiency(%) consistencyandtemperatureonresultsintrials performedwithanindustriallow-speedkneader areshowninFig.14.Increasingpulp consistencyandtemperatureimprovesthe dispersionefficiencyofspecksfromUV varnishes.Fig.15showstheresultsoftrials performedwithahigh-speeddisperserfor dispersionofspecksfromUVvarnishes[52]. Dispersionismoreefficientathightemperature and,accordingtothemachinerysupplier,the implementationofapostdeinkingstageis recommendedforremovalofspeckparticles, whichhavebeenbrokeninsmaller,floatable particles. Kneading 99 90 Dispersing Energyconsumption(kWh/t) 406080100120140160180 CTPpilotplanttrialsonindustrialdevices.Specksfrom UVvarnishes,onlyspeckslargerthan300µmare considered. 9.Summary Dispersiontreatmentisusedprimarilyasameanstoimproveappearancecharacteristicsby disguisingthepresenceofcontaminants.Whenqualitylevelsachievedbycleaningandscreeningare notadequateforaparticularproduct,additionaltechniquescanbeused,whichcanincludedispersion ontheentirepulporonapartofit,afterfractionation.Theaimofadispersingtreatmentisto disperse contaminantstosuchanextentthattheirdetrimentaleffectsarereduced . Dispersionathightemperaturewasusedinitiallyto dispersebitumen whenrecyclingOCC,andlater todisperseothercontaminantssuchaswaxandhotmeltglues . Forwhitegrades,hot-dispersionwasproposedtodisperse hotmeltcontaminants andto improvethe visualaspect bydispersingresidualinkandspecks. Inhigh-speeddisperser,allcontaminantsarereducedinsize.Theywerethenclaimedtoprotect papermachinefromstickies.However,becausedispersiondoesnotremovecontaminants,but dispersesthemintothepulp,itcancreatesomedetrimentaleffectssuchasdepositsonthepaper machine. Asaconsequenceoftheprogressmadeincleaningandscreeningefficiency,hotdispersion hasbeenquestionedinthepaperandboardrecyclingunits . Inbrowngraderecycling,high-speeddisperseristhemostpopulartechniqueused.Theintensityofits actionisdeterminedbythedesignofthedisc,theenergyinput(generallybetween40and80kWh/T), temperature,residencetimeandthegapbetweenthediscs.Narrowdiscgaps,lowtemperatureand highresidencetimeincreasethedispersingintensity(thatallowgooddispersiontobeachieved)but alsoincreasethefreenessloss. Fordeinkingapplication,thefutureofhotdispersionismainlyrelatedtotheimprovementofthe deinkingefficiency.Bothhigh-speeddispersersandlow-speedkneadersareproposedforthe improvementininkdetachment,mainlybeforepost-flotation.Varioushigh-speeddispersingandlow- speedkneadingtechnologiesareproposedandthechoiceofthemosteffectivetypeisthesubjectof debate.Acombinationofthevarioustechnologiesinordertocombinetheadvantagesofeachisalso proposed. Actually,aregainofinterestappearsonthe developmentofpapermechanicalproperties ofthepulp duringthesestages.Undertypicalhigh-speeddispersingconditions,burstandtensilepropertiesare enhanced,similartolowconsistencyrefining,butwithoutthefreenesslosscausedbycuttingin refiner.Underhightemperatureconditions,fibrecuttingisfurtherlimitedinhigh-speeddisperser. High-speeddispersionandlow-speedkneadingcanintroducecurlintothetreatedfibres.Low-speed kneaderinducesmorehigherfibrecurl,mainlybecauseofhigherresidencetime.Thisaffectsthen tearstrength,dimensionalstability,bulk,etc. Newapplications,suchas microbiologicaldecontamination, byusingchemicalsinalow-speed kneader,havealsobeenproposed.

Specifications

| Condition | Used |

| Stock Number | 1102 |